Choosing the right steel fabrication company is crucial to the success of your construction or manufacturing project. With over 40 years of experience, Riteweld Engineering offers insight into what really matters when selecting a steel specialist.

1. ✅ Experience & Expertise

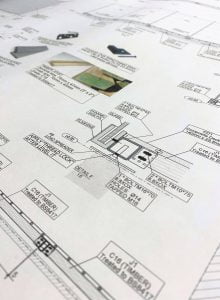

Steel fabrication requires a high level of technical knowledge and hands-on experience. Look for a company with a proven track record across various industries—from commercial construction to industrial installations. A skilled fabricator should be able to interpret technical drawings accurately, work with a wide range of steel types, and understand the tolerances and standards required for each project. Experience also plays a key role in anticipating challenges before they arise and ensuring the structural integrity of every component.

Companies with decades of experience, like Riteweld Engineering, bring valuable insight into site logistics, material sourcing, and fabrication methods that meet UK regulations. Whether it’s a multi-tonne structural steel frame or custom metalwork, experience ensures efficiency, precision, and compliance. Always ask to see examples of past projects, case studies, or testimonials to assess the scope and scale of their capabilities. This gives you confidence that they can deliver to a high standard, on time, and within budget.

👉 Tip: Browse a company’s past projects and case studies to evaluate their versatility. Check out Riteweld’s portfolio of structural steel projects.

2. 🏗 Quality of Work & Certifications

High-quality fabrication isn’t just about clean welds—it’s about compliance with national standards and long-term performance. Ensure your chosen fabricator holds certifications such as:

-

CE Marking to EN 1090

-

ISO 9001 Quality Management

These accreditations guarantee that the fabrication process is controlled, consistent, and safe. CE Marking, in particular, is a legal requirement in the UK for structural steel products and demonstrates that the company meets essential health, safety, and environmental standards. ISO 9001 ensures the company follows strict quality management procedures, helping to reduce errors and improve efficiency across every stage of production.

Choosing a certified steel fabricator also reduces project risks and gives peace of mind to contractors, architects, and developers. It’s a sign of professionalism, accountability, and a commitment to excellence. Always verify these credentials and look for fabricators who are happy to share their compliance documentation and explain how they integrate quality standards into their day-to-day operations. Quality should never be compromised when it comes to structural steelwork.

🔗 External link: UK Government guidance on CE marking

3. 🔧 Full-Service Capabilities

A company that handles everything from design to installation will save you time, reduce miscommunication, and keep your project on schedule. When all services are managed under one roof, there’s better quality control, streamlined communication, and fewer delays caused by third-party coordination.

At Riteweld, we offer:

-

CAD design & structural detailing

-

In-house steel fabrication

-

Nationwide delivery & on-site installation

This full-service approach allows us to take your project from concept to completion with complete transparency and precision. Our experienced team works closely with clients to ensure all specifications are met, including load requirements, compliance with UK building regulations, and integration with existing structures. By handling the fabrication and installation ourselves, we ensure consistency and accountability at every stage. Whether it’s a bespoke metalwork job or a large structural steel framework, having a single, experienced contractor managing the process improves efficiency and ensures high standards of safety, quality, and performance. This also gives you one point of contact, reducing stress and simplifying project management.

👉 Explore our Steel Installation services to learn more.

4. 🚛 Project Turnaround & Delivery

Lead times are critical in construction. A reliable fabricator will offer accurate timeframes and handle delivery logistics efficiently. Delays in steel fabrication can disrupt project timelines, increase costs, and create knock-on effects for other trades on-site. That’s why choosing a fabricator with the capacity and flexibility to meet deadlines is essential.

Ask questions like:

-

How quickly can you begin fabrication?

-

Do you offer nationwide delivery?

-

What’s your turnaround time for standard jobs?

It’s also important to assess their workshop capacity, stock availability, and transport capabilities. Some fabricators may have in-house transport fleets, while others rely on third-party logistics—this can impact how quickly materials reach your site. At Riteweld Engineering, we understand the importance of fast, dependable service. Our team works to realistic lead times, with clear communication at every stage, ensuring your steel arrives exactly when needed. Whether you’re working on a tight schedule or coordinating with multiple contractors, having a fabricator who prioritises timely delivery is a major advantage.

5. 📍 Local Presence & National Reach

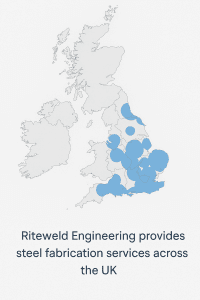

Choosing a locally based fabricator with national coverage offers the best of both worlds. Riteweld Engineering is based in Banbury, Oxfordshire, but we work with clients across the UK. This means you get the personal service of a local team with the capability to manage nationwide structural steel projects. Being centrally located allows us to access major transport routes quickly, helping us deliver materials and complete on-site work efficiently, no matter where your project is based.

We’ve successfully completed structural steelwork in locations ranging from Scotland to Wales, showing our flexibility and reach. Working with a fabricator that understands local building regulations while offering national experience ensures your project meets all compliance standards, whether it’s in a city centre or rural development. You’ll benefit from clear communication, reliable lead times, and the peace of mind that comes from working with a team that values quality, consistency, and client satisfaction—wherever you are in the UK. Our ability to mobilise skilled teams and deliver to site means we can support projects of any scale or complexity.

👉 Contact us to discuss your next project: Get in touch here

✅ Summary: What to Look For

When choosing a steel fabrication company, ensure they offer:

Proven experience & certifications

High-quality materials & welding practices

Full design-to-installation services

Transparent lead times

Local accessibility with national capability

For steel fabrication done right the first time, trust Riteweld Engineering. With over 40 years of industry experience, we deliver precision, professionalism, and performance.